The "Golden Showerhead" of Semiconductors: Why Does It Cost Tens of Thousands?

Today, the semiconductor industry stands as a cornerstone of a nation’s advanced manufacturing capabilities and technological prowess, playing a pivotal role in economic development and scientific progress.

The semiconductor sector’s technological foundation rests on two pillars: equipment and materials. While semiconductor equipment is typically assembled, every component within it can dictate the performance of the entire machine—ultimately determining the success or failure of chip fabrication. Critical components like electrostatic chucks, guide rails, seals, and bearings are indispensable for meeting equipment performance targets.

Today’s protagonist: The gas distribution plate (Showerhead)—a "hidden hero" in semiconductor manufacturing known for its exorbitant price tag.

01 A High-Priced "Showerhead"

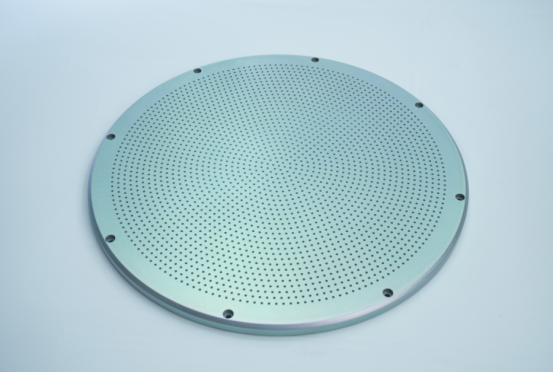

The gas distribution plate, or Showerhead, is colloquially dubbed the "semiconductor showerhead" or "uniform gas diffuser." Resembling a bathroom showerhead in appearance, its price tag dwarfs household versions—reaching tens of thousands of dollars.

Its surface is densely perforated with hundreds to thousands of microscopic holes, forming a precision-engineered neural network that meticulously controls gas flow rates and injection angles. This ensures every square millimeter of a wafer is uniformly "bathed" in process gases, enhancing production efficiency and product quality.

The Showerhead is indispensable in critical processes such as cleaning, etching, and deposition, directly influencing semiconductor process precision and product quality.

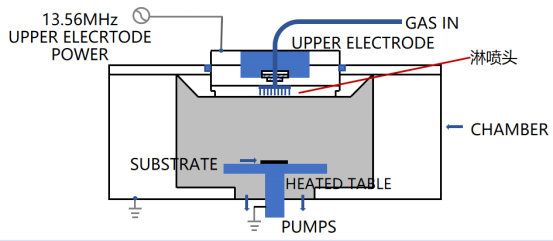

In deposition processes (e.g., CVD):

1、Thin Film Deposition: CVD is used to deposit materials like silicon dioxide (SiO₂), polysilicon (poly-Si), or metal oxides (e.g., titanium dioxide, TiO₂). The Showerhead mixes and injects precursor gases (e.g., silane, metal-organic compounds) onto the substrate, triggering chemical reactions to form the desired film.

2、Crystal Growth: For single-crystal silicon wafer production, the Showerhead delivers precursor gases into the reaction chamber. By controlling parameters like gas flow, concentration, and injection speed, it enables uniform deposition of precursors onto the substrate, fostering single-crystal growth.

3、Reaction Environment Control: The Showerhead regulates chamber atmosphere and temperature, providing precise gas mixtures and uniform distribution to stabilize the deposition process.

4、Tailored Performance: Optimized Showerhead designs and operating parameters ensure uniform film thickness, quality, and consistency, meeting diverse semiconductor material demands.

02 Extreme Precision: Why Is It as Pricey as Gold?

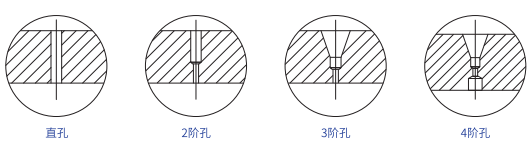

During wafer processing, the Showerhead’s surface is riddled with microholes (0.2–6 mm diameter). These holes channel specialty gases through a labyrinth of precision-engineered pathways, depositing gases uniformly across the wafer.

Achieving uniform film thickness and consistency demands near-zero tolerance for hole diameter deviations or burrs—imperfections risk uneven deposition and reduced process yields.

Manufacturing Challenges:

Brittle Materials: Showerheads are often made from fragile materials (e.g., monocrystalline silicon, quartz, ceramics) prone to cracking under stress.

Ultra-Deep Microholes: Holes with a depth-to-diameter ratio exceeding 50x are invisible during drilling, complicating heat dissipation and chip removal. Overheating or chip clogging can fracture drill bits.

Plasma-Assisted Processes: In PECVD or dry etching, the Showerhead acts as an electrode, generating uniform electric fields via RF power to stabilize plasma distribution and deposition/etching uniformity.

03 Material Selection Matters

Given the corrosive, high-temperature, or high-pressure gases in semiconductor manufacturing, Showerheads employ corrosion-resistant materials. Depending on application and precision requirements, they fall into two categories:

1. Metal Showerheads

Materials: Aluminum alloy, stainless steel, nickel alloys.

Aluminum Advantages: High thermal conductivity, corrosion resistance, cost-effectiveness, and machinability.

2. Non-Metal Showerheads

Materials: Monocrystalline silicon, quartz, ceramics (e.g., CVD-SiC, alumina, silicon nitride).

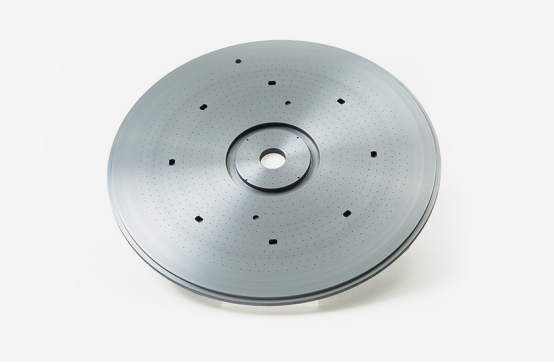

AMTD Anhui Boshine Microelectronics Technology Co., Ltd. specializes in high-precision Showerhead solutions for semiconductor equipment. Its product portfolio includes Shower heads, Face plates, Blocker Plates, Top Plates, Shields, Liners, Pumping rings, Edge Rings, and other core components, widely used in semiconductor and display panel manufacturing. Renowned for exceptional performance, AMTD’s solutions command strong market recognition.

References: Semiconductor Equipment News, Knife Industry Journal, Huafu Securities Research Institute, Powder Technology Network.