Semiconductor Showerhead/Gas Distribution Plate/Gas Dispersion Plate

In semiconductor manufacturing processes, the Showerhead and its functionally equivalent components—Gas Distribution Plates and Gas Dispersion Plates—are critical parts in wafer processing. Particularly in thin-film deposition processes such as Chemical Vapor Deposition (CVD) and Atomic Layer Deposition (ALD), their performance directly impacts wafer yield, film uniformity, and equipment efficiency. Below is a detailed breakdown covering technical principles, structural functions, application scenarios, and development trends.

I. The "Nanometer-Level Precision" Challenge in Gas Distribution

The core function of a Showerhead is to uniformly disperse process gases across the wafer surface, ensuring highly consistent film thickness and composition. Its operation relies on three key technologies:

1. Gas Flow Field Control

o Uses micro-hole arrays or slit structures to convert concentrated gas input into low-turbulence, highly uniform laminar flow, preventing local concentration fluctuations that cause film thickness variations.

2. Thermal Field Co-Design

o In high-temperature processes (e.g., ALD at >600°C), the Showerhead must coordinate temperature control with the wafer stage to prevent structural deformation due to thermal stress, which could disrupt gas distribution accuracy.

3. Material Corrosion Resistance

o Must withstand prolonged exposure to corrosive gases like HF (Hydrogen Fluoride) and Chlorine (Cl₂). High-purity ceramics (e.g., Alumina, Aluminum Nitride) or corrosion-resistant alloys (e.g., Hastelloy) are used to ensure longevity.

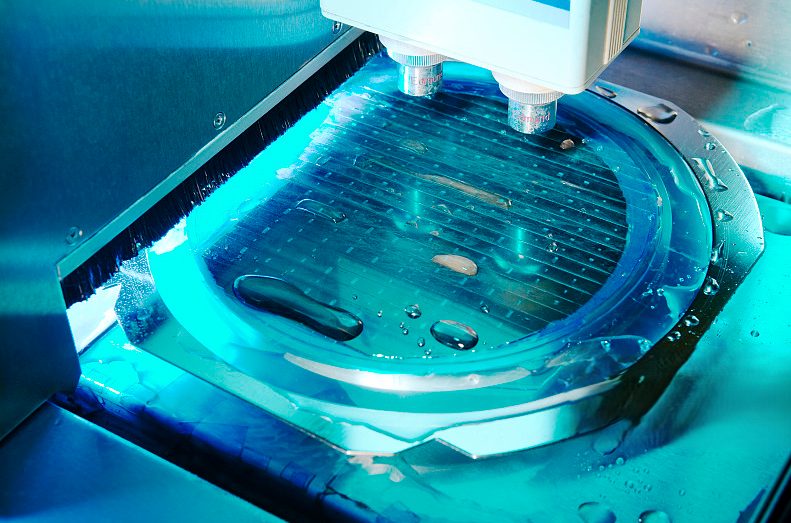

II. "Nanometer-Level Engineering" in Precision Machining

A typical Showerhead consists of the following modules:

1. Gas Distribution Chamber

o Internal channels are optimized using computational fluid dynamics (CFD) to minimize pressure loss and ensure uniform gas flow.

2. Micro-Hole Array / Slit Structure

o Micro-hole type: Apertures typically range from 0.1–1 mm, with precise spacing to eliminate "edge effects" that cause abnormal film thickness at wafer edges.

o Slit type: Uses radial or concentric slits for uniform gas coverage, ideal for large wafers (e.g., 12-inch).

3. Heating / Temperature Control Components

o High-end Showerheads integrate resistive heaters or thermocouples for ±1°C temperature control, meeting stringent thermal stability requirements in ALD processes.

4. Sealing & Connection Interfaces

o Utilizes metal gaskets (e.g., C-seals) or vacuum welding to ensure chamber leakage rates below 1×10⁻⁹ Pa·m³/s.

III. The "Precision Foundation" of Thin-Film Deposition

Showerhead performance directly determines key process metrics:

1. CVD Processes

o In polysilicon or silicon nitride deposition, film thickness uniformity must be ≤±1% (across the entire wafer) to ensure consistent device electrical performance.

2. ALD Processes

o For High-K dielectrics and metal gates in 3nm and below nodes, single-atom-layer deposition precision is required, demanding gas concentration fluctuations <0.1%.

3. Advanced Packaging

o In TSV (Through-Silicon Via) copper filling and RDL (Redistribution Layer) processes, zone-controlled flow technology adapts gas distribution for complex 3D structures.

IV. Intelligence & Material Revolution

1. AI-Driven Dynamic Calibration

o Embedded sensors monitor gas flow and temperature in real time, while machine learning algorithms adaptively adjust aperture openings to compensate for performance degradation over time.

2. Composite Material Breakthroughs

o Silicon Carbide (SiC) Coating: Enhances plasma etch resistance, extending lifespan to >100,000 hours (vs. ~30,000 hours for traditional ceramics).

o Graphene-Reinforced Structures: Leverage high thermal conductivity to optimize heat distribution, reducing deformation risks from thermal stress.

3. Modular Design

o Enables rapid replacement of micro-hole plates or slit modules, minimizing equipment downtime and maintenance costs.

V. Conclusion

As a "nanometer-precision valve" in semiconductor equipment, the Showerhead evolves in lockstep with advanced node scaling. With the mass production of sub-3nm processes and the extreme uniformity demands of AI chips and HBM (High-Bandwidth Memory), this niche field will continue driving cross-disciplinary innovation in materials science, precision manufacturing, and fluid dynamics.

AMTD provides high-precision Showerhead solutions for core components, including Shower Head, Face Plate, Blocker Plate, Top Plate, Shield, Liner, Pumping Ring, and Edge Ring. These critical semiconductor components are widely used in semiconductor and display panel industries, delivering exceptional performance and high market recognition.

Sources:

· Introduction to Semiconductor Manufacturing Technology (3rd Edition)

· Applied Materials Technical Whitepapers

· Lam Research 2024 Semiconductor Equipment Trends Report

· China Electronic Special Equipment Industry Association (CESEIA) Research Data