FerroTec Showcases Ecosystem at 2025 Haining Expo丨Bocore Micro Debuts Chip-Level Showerhead

Gathering the 'Core' and Building the 'Chain', Standing Brave at the 'Forefront'." On the morning of May 8th, the 2025 China Zhejiang (Haining) Semiconductor Equipment and Materials Expo, guided by the China Semiconductor Industry Association and hosted by the Zhejiang Semiconductor Industry Association, officially opened at the Haining Convention and Exhibition Center. As the first semiconductor-themed expo in Zhejiang Province, this event featured both online and offline exhibitions, with five major exhibition areas: wafer manufacturing equipment, packaging and testing equipment, compound semiconductors, core components and materials, and EDA/IP design services. It attracted renowned industry experts, corporate representatives, and leaders from various industry associations, all gathering to discuss cutting-edge semiconductor technologies, market trends, and collaborative innovation.

Under the invitation of the Hangzhou Binjiang District Economic and Information Bureau, Ferrotec Group (China)'s subsidiaries, including Hangzhou Ferrotec Electronics Co., Ltd. and Hangzhou Deyuan Core Semiconductor Technology Co., Ltd., joined forces with eight other companies such as Hangzhou Changchuan Technology Co., Ltd., Hangzhou Guangliwei Electronics Co., Ltd., and Hangzhou Sanxiang Technology Co., Ltd., to form the Hangzhou Binjiang exhibition group. Together, they showcased the district's comprehensive industrial chain layout in semiconductor materials, equipment, testing, and smart manufacturing. A representative from the Binjiang District Economic and Information Bureau stated that the group participation aimed to strengthen regional semiconductor industry synergy, providing a high-quality platform for technical exchange and collaboration among semiconductor companies and further promoting deep integration across the industrial chain's upstream and downstream sectors.

Exhibited Products

The Quartz Division of Ferrotec Electronics displayed products such as cleaning boats (packaging), substrate holders, and quartz wafers at the expo. These are critical consumable components in key semiconductor manufacturing equipment, widely used in 150mm-300mm semiconductor processes including diffusion, etching, epitaxy, wet cleaning, and RTP. Technical experts from Ferrotec Electronics provided detailed explanations of these quartz components' outstanding performance in high purity, high-temperature resistance, and corrosion resistance, as well as how their precision machining meets the stringent requirements for material stability and consistency in semiconductor manufacturing.

The Vacuum Division of Ferrotec Electronics highlighted its semiconductor vacuum chambers and magnetic fluid vacuum sealing transmission devices. These products are primarily used in high-end manufacturing fields such as semiconductor equipment, photovoltaic production, and vacuum coating, offering excellent corrosion resistance, high sealing performance, and long lifespan. A technician from the Vacuum Division explained at the booth, "We provide 14 surface treatment technologies, including electroless nickel plating, natural anodizing, and hard anodizing, significantly enhancing the wear resistance and surface vacuum level of metal components, ensuring uniformity and reliability in complex precision parts. Our independently developed magnetic fluid vacuum sealing transmission devices break through the limitations of traditional mechanical seals, achieving zero-leakage transmission in ultra-high vacuum environments."

As a leading supplier of temperature control system solutions for the semiconductor industry, the Thermoelectric Division of Ferrotec Electronics attracted numerous visitors with its special liquid chillers and semiconductor chillers. These products employ innovative temperature control technologies, achieving ultra-high precision temperature stability of ±0.01°C, fully meeting the stringent temperature requirements of semiconductor manufacturing processes. At the expo, a technician from the Thermoelectric Division elaborated on the core advantages of their chillers: "Our chillers offer a temperature control range of -100°C to 200°C with precision up to ±0.01°C, dedicated to providing professional temperature control solutions for clients in semiconductors, testing, lasers, medical, energy storage, and liquid cooling." Notably, the Thermoelectric Division recently launched its latest chiller model, the FCCWS051-7402 series, designed for semiconductor industry etching applications. The division head stated that future efforts will focus on optimizing product performance and enhancing differentiated competitiveness to provide more reliable temperature control技术支持 for the localization of semiconductor equipment.

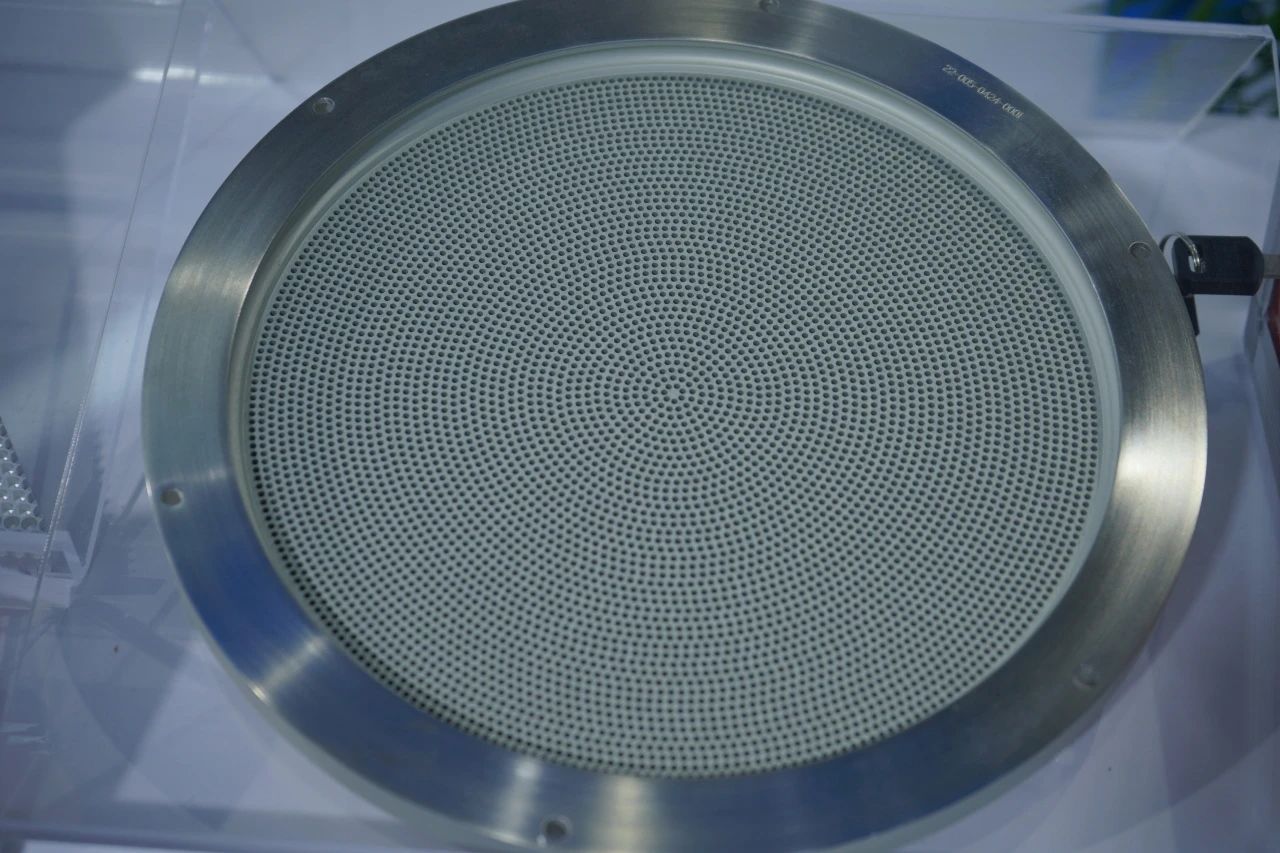

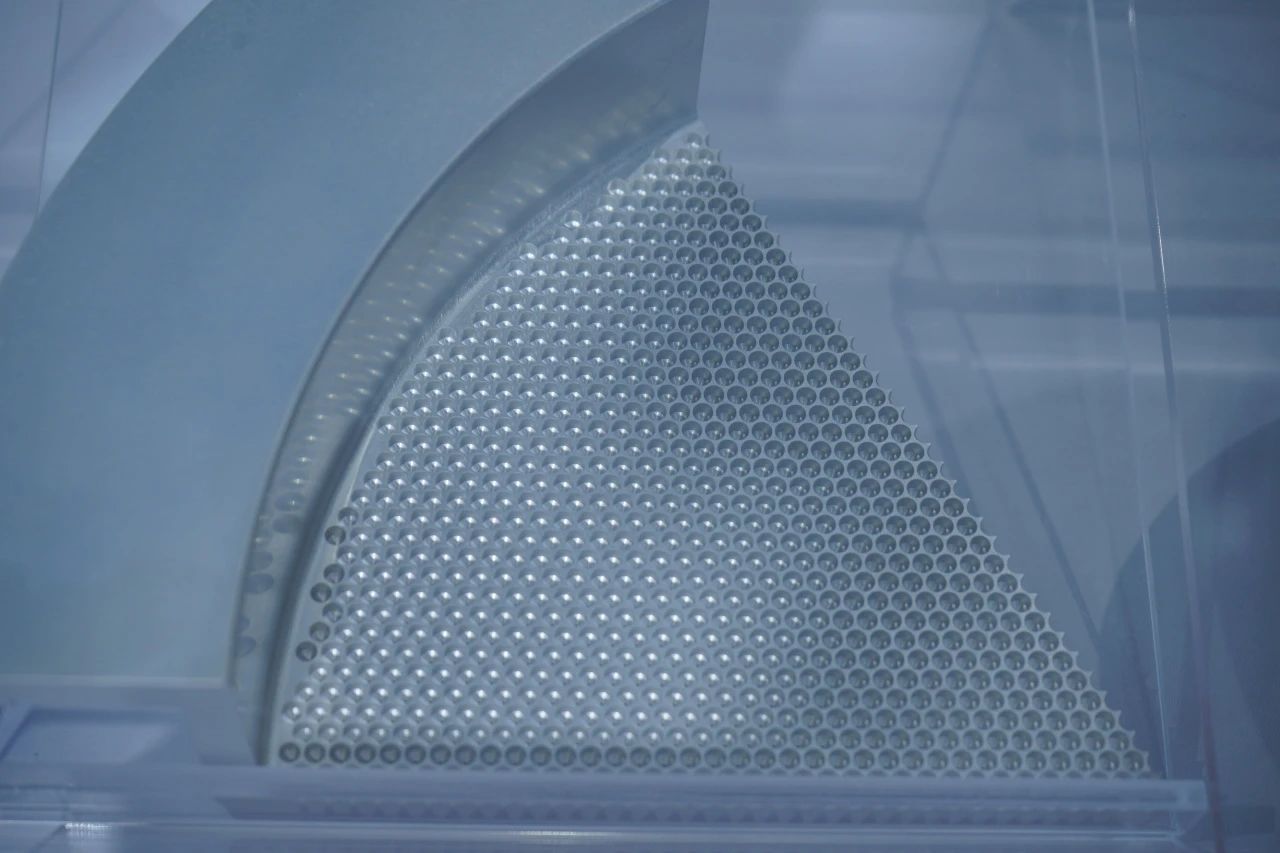

Hangzhou Deyuan Core Semiconductor Technology Co., Ltd., a core subsidiary of Ferrotec Group, showcased showerheads and silicon rings at the expo, demonstrating its technical prowess in critical semiconductor components. Showerheads are essential in wafer manufacturing etching processes, serving as the pathway for etching gas into the chamber and acting as electrodes to generate plasma. Silicon rings, on the other hand, provide an etching environment and focus plasma during the process, optimizing edge etching on wafers. These products are widely used in etching and other critical equipment from mainstream semiconductor manufacturers globally.

Also exhibited were the showerhead products from Anhui Boxinwei Semiconductor Technology Co., Ltd., a gas distribution device widely used in semiconductor manufacturing processes. Their products feature high precision, high cleanliness, and multi-layer composite surface treatments, ensuring uniform gas distribution over wafers without impurities or contamination, thereby improving manufacturing quality and yield.

The 2025 China Zhejiang (Haining) Semiconductor Equipment and Materials Expo concluded successfully, with Ferrotec Group and its subsidiaries comprehensively showcasing their technical capabilities and innovative achievements in critical semiconductor components, materials, and equipment. Moving forward, we will continue to deepen our focus on the semiconductor industrial chain, providing higher-quality products and services to support the high-quality development of China's semiconductor industry. We look forward to collaborating with industry partners to drive technological innovation and industrial.