Efficient Ultrasonic Cleaning for Semiconductor Particle Removal

Ultrasonic cleaning technology, as an advanced surface treatment method, has demonstrated efficient practice in removing particles in semiconductor manufacturing. This technology utilizes the cavitation effect, acceleration effect, and straight-flow effect of ultrasonic waves in a liquid to directly act on the liquid and contaminants, achieving efficient cleaning.

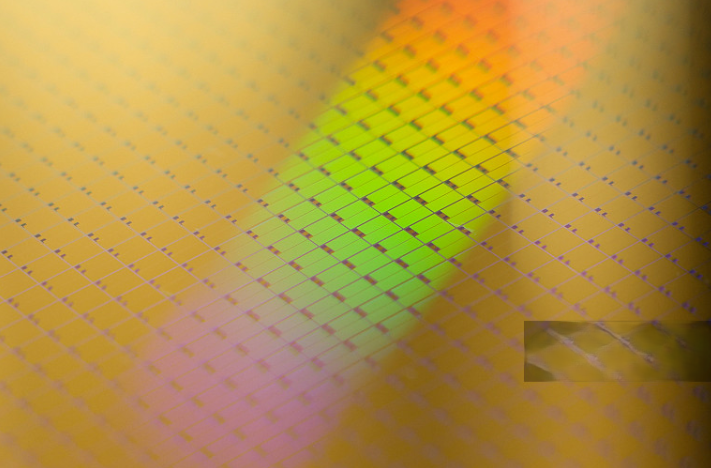

In semiconductor manufacturing, ultrasonic cleaning technology is widely applied to remove particles and contaminants from the surface of wafers. During the manufacturing process of wafers, they are subject to various types of contamination, such as dust in the air, particles generated by equipment friction, and chemical reagent residues. These particles typically have sizes in the micrometer or even nanometer range, making it difficult for traditional cleaning methods to completely remove them. Through a multi-step process including hot dipping, spray rinsing, ultrasonic cleaning, cold rinsing, and hot air drying, contaminant particles on the workpiece surface can be thoroughly removed, achieving extremely high cleanliness standards.

The principle of ultrasonic cleaning lies in the fact that when ultrasonic waves propagate, they cause particles in the elastic medium to oscillate. The acceleration of the particle vibration is proportional to the square of the ultrasonic frequency. Ultrasonic waves at tens of kilohertz generate extremely large forces, creating acoustic cavitation. When the cavitation bubbles suddenly collapse, the shock waves emitted can generate thousands of atmospheric pressures around them, directly and repeatedly impacting the contaminant layer. On one hand, this breaks the adhesion between the contaminants and the surface of the cleaned object; on the other hand, it causes the contaminant layer to break down and detach from the surface of the cleaned object and disperse into the cleaning liquid, thereby achieving a clean surface.

In addition, ultrasonic cleaning technology also features simple operation and ease of automation. By combining it with automated equipment such as robots, automated control of the cleaning process can be achieved, improving production efficiency and product quality. For example, in an automated wafer cleaning production line, robots accurately grasp the wafers and sequentially place them into hot dipping tanks, spray rinsing tanks, ultrasonic cleaning tanks, etc. for cleaning, followed by hot air drying. The entire process is precisely controlled to ensure consistent cleaning results.

With the increasing integration of semiconductor devices, higher requirements have been placed on cleaning technology. Multi-frequency ultrasonic cleaning technology has emerged accordingly. By simultaneously or alternately using ultrasonic waves of different frequencies, it effectively removes particles over a wide range of sizes. High-frequency ultrasonic waves are suitable for small particles, while low-frequency ultrasonic waves have better cleaning effects on larger particles, meeting the cleaning needs for particles of different sizes.

AMTD provides high-precision Showerhead (spray head/gas distribution plate/gas diffuser) services for core components. Its products mainly include semiconductor equipment core parts such as Showerhead, Face plate, Blocker Plate, Top Plate, Shield, Liner, pumping ring, and Edge Ring. These products are widely applied in fields such as semiconductors and display panels, boasting excellent performance and high market recognition.

Content sources: Cleaning Technologies in Microelectronics Manufacturing, Introduction to Surface Treatment Processes