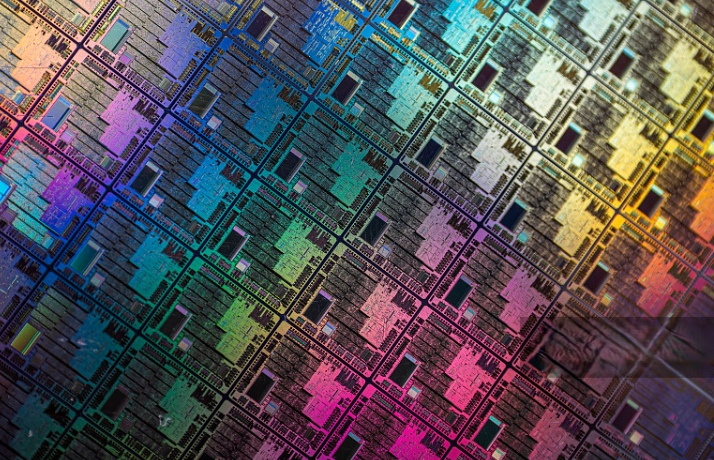

Electropolishing & Passivation for Enhanced Semiconductor Metal Surfaces

Electropolishing and passivation treatment, acting as a powerful duo for enhancing semiconductor metal surface performance, play an indispensable role in semiconductor manufacturing. Electropolishing achieves smooth and bright surface treatment of workpieces by utilizing the principle that microscopic protrusions on the metal surface undergo anodic dissolution first in a specific electrolyte under appropriate current density.

In semiconductor manufacturing, the electropolishing process is widely applied to treat key components such as metal lead frames and wafer carrier rings. By precisely controlling parameters such as electrolyte composition, temperature, voltage, and current density, high-quality polishing results can be obtained. For instance, using an electrolyte with sulfuric acid and phosphoric acid as the basic components, at a certain temperature, the workpiece is connected to the positive terminal of a DC power source as the anode. Conductive materials resistant to electrolyte corrosion, such as lead and stainless steel, are used as the cathode and connected to the negative terminal of the DC power source. Both are immersed in the electrolyte at a certain distance apart.

After a certain period of energization, the tiny protrusions on the workpiece surface dissolve first, gradually transforming into a smooth and bright surface. This enhances the surface quality and electrical properties of the components, reduces issues such as electric field concentration caused by surface roughness, and improves the reliability of the devices.

The introduction of pulse electropolishing technology has further enhanced the effectiveness of electropolishing. Traditional DC electropolishing suffers from problems such as high energy consumption and uneven surface quality. Pulse electropolishing effectively reduces energy consumption by periodically changing the direction and magnitude of the current while improving surface flatness and glossiness. This technology excels in treating high-precision metal components, such as metal sensors in MEMS (Micro-Electro-Mechanical Systems), meeting their extremely high requirements for surface quality.

Passivation treatment, on the other hand, utilizes the oxidizing substances in the passivation solution to promote the formation of a dense passivation film on the metal surface, enhancing the metal's corrosion resistance and stability. This passivation film not only effectively prevents the metal from being oxidized or corroded again but also increases its wear resistance and corrosion resistance.

Passivation treatment offers numerous advantages. The passivation solution is stable and non-volatile, allowing for reuse, which saves over 40% of costs compared to anti-rust oil. The treated workpiece surface is free of greasiness and clean. The formed passivation film is more robust, difficult to damage and remove, and has more stable performance, with corrosion resistance increased by 8 - 50 times. The oxygen molecule structure passivation film formed on the metal surface through passivation is dense and stable, and it also has a self-repairing effect in the air, providing a strong guarantee for the long-term stable operation of semiconductor devices.

AMTD provides high-precision Showerhead (spray head/gas distribution plate/gas diffuser) services for core components. Its products mainly include semiconductor equipment core parts such as Showerhead, Face plate, Blocker Plate, Top Plate, Shield, Liner, pumping ring, and Edge Ring. These products are widely applied in fields such as semiconductors and display panels, boasting excellent performance and high market recognition.

Content sources: Metal Surface Treatment and Protection Technologies, Introduction to Surface Treatment Processes