Anodizing Aluminum Alloys: Decorative & Durable Semiconductor Metal Treatment

Aluminum alloy anodizing, as an electrochemical reaction process, demonstrates a perfect combination of decoration and durability for semiconductor metals. In this process, the metal or alloy serves as the anode and reacts with ions in the electrolyte under the action of an externally applied current, resulting in the formation of an oxide film on the metal surface.

This oxide film possesses a variety of excellent properties, such as wear resistance, corrosion resistance, and insulation. In semiconductor manufacturing, aluminum alloy anodizing is commonly used to treat components such as metal casings and brackets. Through anodizing treatment, the surface hardness and wear resistance of these components can be significantly improved. The hardness of ordinary anodized films is approximately HV300, while that of hard anodized films can reach HV500, greatly extending their service life. For example, in the treatment of metal casings for semiconductor equipment, the anodized film can effectively resist friction and collisions during daily use, maintaining the integrity and aesthetic appeal of the casings.

At the same time, the oxide film also offers good decorative effects. It can be dyed and colored to achieve a diverse range of appearances, enhancing the market competitiveness of the products. By adjusting the electrolyte composition and oxidation process parameters, oxide films of different colors can be obtained to meet the personalized appearance requirements of different customers.

In addition, the aluminum alloy anodized film has a high insulation resistance and breakdown voltage (1.5KV), making it suitable for use as the dielectric layer of electrolytic capacitors or the insulating layer of electrical appliances. In semiconductor circuits, some key parts require good insulation performance, and the anodized film can effectively meet this requirement, ensuring the normal operation of the circuits. Its excellent thermal insulation properties also make it widely applicable in components that operate under instantaneous high temperatures, such as preventing the melting of aluminum. In some high-temperature process steps in semiconductor manufacturing, it can protect metal components from damage.

With the development of semiconductor technology, higher requirements have been placed on the aluminum alloy anodizing process. Nanoscale anodizing technology is gradually emerging. By precisely controlling the oxidation conditions, an oxide film with a nanoscale structure can be formed on the surface of aluminum alloys, further improving their properties, such as wear resistance, corrosion resistance, and insulation, providing more advanced technical means for the treatment of aluminum alloy components in semiconductor manufacturing.

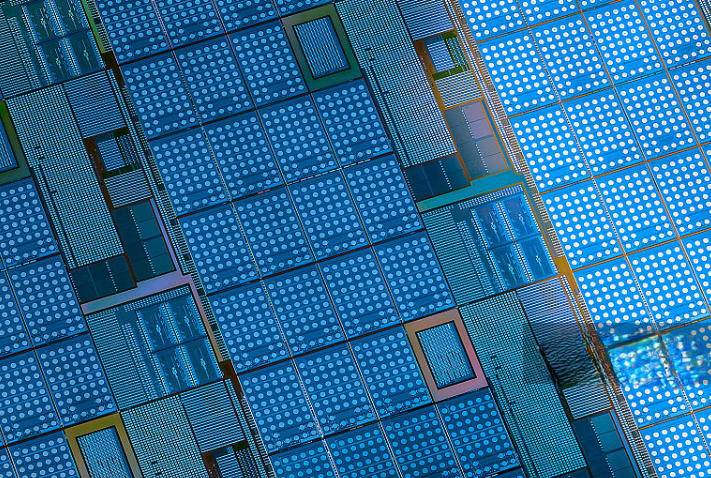

AMTD provides high-precision Showerhead (spray head/gas distribution plate/gas diffuser) services for core components. Its products mainly include semiconductor equipment core parts such as Showerhead, Face plate, Blocker Plate, Top Plate, Shield, Liner, pumping ring, and Edge Ring. These products are widely applied in fields such as semiconductors and display panels, boasting excellent performance and high market recognition.

Content sources: Aluminum Alloy Surface Treatment Technologies, Introduction to Surface Treatment Processes