I. Metal Material Surface Treatment

1. Protective Treatment

Electroplating/Electroless Plating

· Electroplating: A process of depositing metals such as nickel, chromium, and zinc onto the metal surface through electrolysis to enhance corrosion resistance (e.g., chromium plating on bathroom hardware).

· Electroless Plating: Depositing a metal layer under current-free conditions, offering good uniformity (e.g., electroless nickel plating on stainless steel).

Hot-dip Galvanizing

Immersing metal into molten zinc to form a wear-resistant and corrosion-resistant coating, suitable for outdoor steel structures (e.g., guardrails and steel frameworks).

Anodizing

The main treatment method for aluminum alloys, generating a porous oxide film that can be dyed (e.g., colored oxidation on mobile phone frames) or sealed to enhance corrosion resistance.

2. Decorative Treatment

Brushing/Polishing

· Brushing: Creating textures through mechanical friction (e.g., straight or random brushing on stainless steel panels). Polishing includes mechanical polishing (for high gloss) and electrolytic polishing (for a smooth surface).

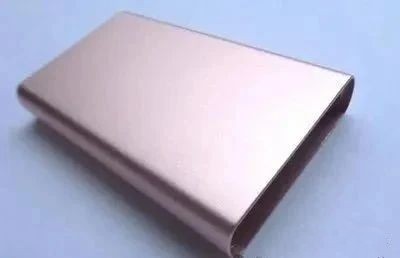

PVD (Physical Vapor Deposition)

Depositing metals such as titanium and chromium nitride in a vacuum environment, resulting in a metallic color (e.g., rose gold PVD on watch cases), with high hardness and scratch resistance.

Spray Coating/Baking Paint

· Electrostatic Spray Coating: Powder coating adheres to the metal surface and is cured at high temperatures (e.g., on home appliance shells). Baking paint offers high gloss and strong adhesion (e.g., on automobile bodies).

3. Functional Treatment

Passivation

Forming a passive film on stainless steel using chemicals such as nitric acid to prevent rusting (e.g., on medical devices).

Blackening (Boiling Black)

Generating a black oxide film on the steel surface to prevent rust and improve appearance (e.g., on knives and screws).

II. Metal Forming Processes

1. Fusion Forming

Casting

· Sand Casting: Low cost and suitable for large parts (e.g., machine tool bases).

· Die Casting: High-pressure and high-speed filling, offering high precision (e.g., aluminum alloy die-cast parts for automobile transmission cases).

· Investment Casting: For complex and precision parts (e.g., jewelry and aviation engine blades).

3D Printing (Metal)

· Selective Laser Melting (SLM): Directly printing high-strength metal parts (e.g., customized medical devices and aerospace components).

2. Plastic Forming

Forging

· Free Forging: Manual or mechanical hammering (e.g., for tools and blanks).

· Die Forging: Forming with a mold, providing excellent mechanical properties (e.g., for automobile gears and crankshafts).

Stamping

Including blanking, punching, bending, and drawing, suitable for mass production of sheet metal parts (e.g., automobile body panels and beverage cans).

3. Cutting Forming

CNC Machining

High-precision milling and turning, suitable for complex structural parts (e.g., aluminum alloy mobile phone frames and precision molds).

AMTD provides high-precision Showerhead services for core components. Its products mainly include Shower head, Face plate, Blocker Plate, Top Plate, Shield, Liner, pumping ring, Edge Ring, and other semiconductor equipment core parts. These products are widely used in the semiconductor and display panel industries, with excellent performance and high market recognition.

Information Source: Proe and Creo Structural Design Tutorial WeChat Official Account