Why Focus on the Producer Series?

The Producer series is Applied Materials' (AMAT) flagship platform for single-wafer PECVD/CVD in the 300mm era, widely used for low-k material deposition, dielectric layers (SiO₂, SiN), barriers/liners, and various other processes. This platform features multi-chamber parallelism, high automation, and high throughput, suitable for 28nm to 7nm and even more advanced processes.

Core Advantages of the Producer Series:

Multi-Chamber Parallelism: Supports various deposition chamber configurations, enhancing productivity.

Plasma Control: High-density PECVD improves deposition uniformity and stress control.

Automation & AI Monitoring: Suitable for large-scale mass production, improving yield rates.

High Scalability: Supports 28nm to 7nm and even lower nodes, with functional module upgrades to meet future demands.

However, the Producer is not without competitors in the CVD/PECVD field. Let's compare the main competing models and their pros and cons.

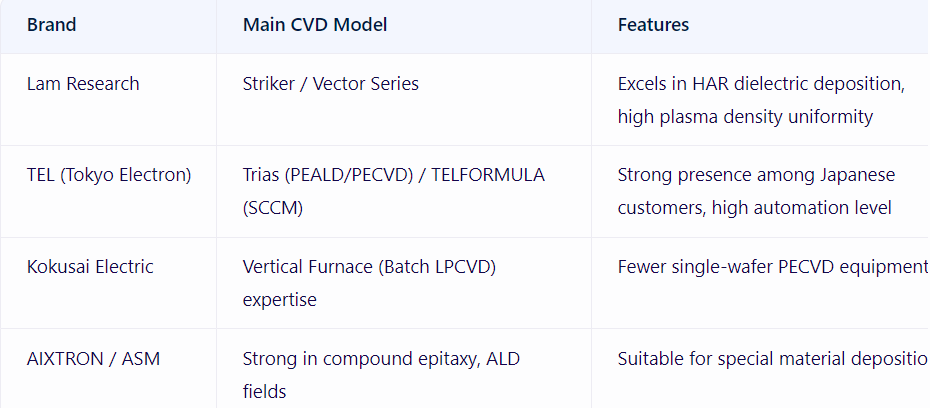

Main Competitors and Corresponding Equipment

In the single-wafer PECVD/CVD equipment market, the AMAT Producer mainly faces the following competitors:

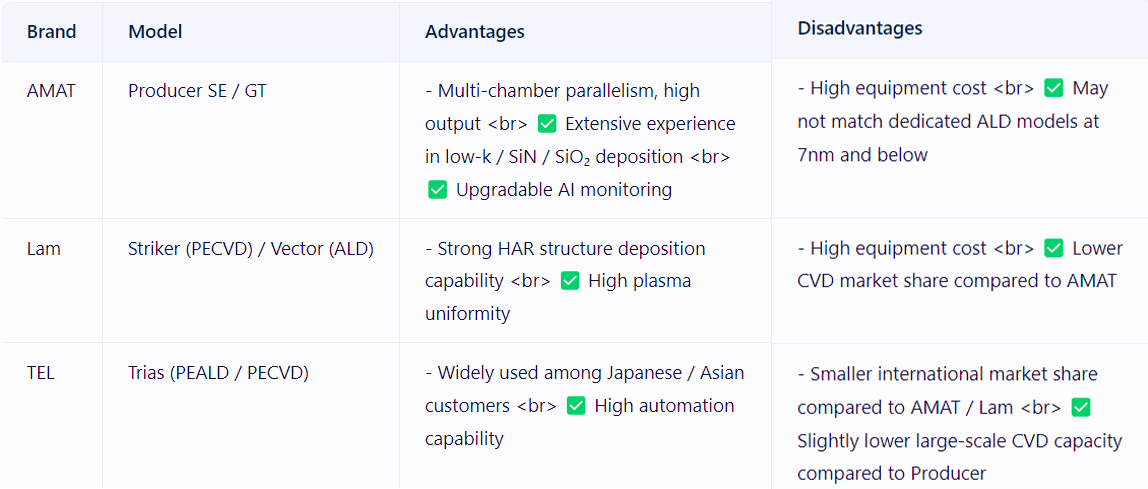

Producer vs. Lam vs. TEL: Comparison Under the Same Process

Below is a comparison of AMAT Producer, Lam Striker, and TEL Trias equipment, using dielectric layer PECVD (SiO₂/SiN/Low-k) as an example.

ummary:

AMAT Producer: Suitable for large-scale mass production, high deposition rate, mature process.

Lam Striker/Vector: Excellent in HAR structure deposition and combination of ALD/PECVD.

TEL Trias: Widely used among Japanese / Korean customers, high automation level, but smaller international market share.

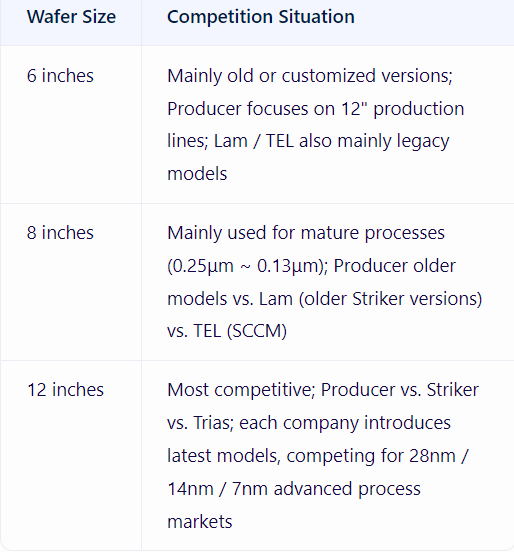

Competitive Landscape by Wafer Size (6" / 8" / 12")

The 12" production line is the main battlefield, with AMAT, Lam, and TEL all introducing the latest models, and competition is particularly fierce.

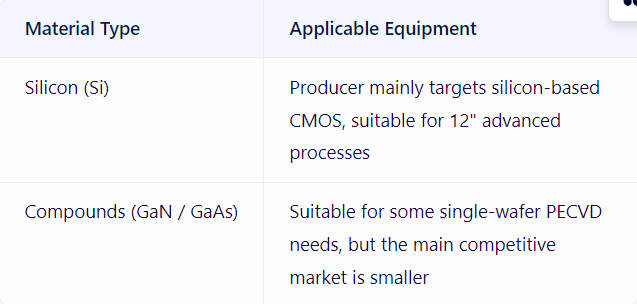

Segmentation by Semiconductor Material (Silicon vs. Compound Semiconductor)

The Producer mainly targets silicon CMOS; the compound semiconductor market is relatively smaller, and MOCVD equipment (AIXTRON / Veeco) dominates compound deposition.

Conclusion: How to Choose the Right CVD Equipment?

For large-scale mass production (300mm CMOS), AMAT Producer SE / GT has high market recognition.

For HAR structures (3D NAND / FinFET), Lam Striker CVD excels in high-aspect-ratio deposition.

For Japanese customers or high automation needs, TEL Trias is a good choice.

For compound semiconductors (GaN / GaAs), MOCVD equipment (AIXTRON / Veeco) is more competitive.

AMAT Producer leads the market share in the CVD/PECVD field, with mature process advantages in 28nm ~ 7nm and 3D NAND / FinFET structures. Lam and TEL also have their own competitiveness in different sub-fields. Customers need to consider productivity, cost, and process requirements comprehensively to make the optimal choice.

Source: WeChat Official Account "Xiaobo's Semiconductor World"