Why focus on DISCO?

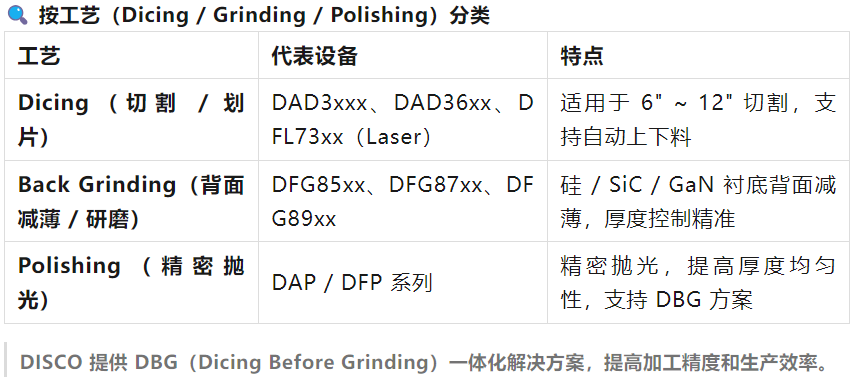

In the back-end process of semiconductor manufacturing, dicing, back grinding, and polishing are critical processes to ensure chip yield and package quality. As a global leading supplier of semiconductor processing equipment, DISCO specializes in these back-end processing steps, providing core equipment such as high-precision dicing saws, laser dicing syst

Today, I will take you on a quick tour of DISCO's main products for different wafer sizes (6", 8", 12") and semiconductor materials (silicon vs. compound semiconductors), and analyze their applications, characteristics, and industry competitive landscape through technical comparisons.

Equipment classified by wafer size:

For 6-inch (150 mm) wafers:

Suitable for compound semiconductors (GaAs / GaN / InP) and power / discrete devices.

Dicing Saw: DAD series (low-throughput model), ideal for dicing 6" GaAs / SiC wafers.

Grinding: DFG / DG series, suitable for grinding 6" wafers.

Polishing: DAP series (precision polishing), ideal for surface treatment of GaAs/GaN substrates.

The market for 6" production lines is relatively small, and DISCO mainly offers customized solutions or upgrades for older models.

For 8-inch (200 mm) wafers:

Suitable for analog / MEMS / automotive power devices / sensors.

Dicing: DAD32xx / DAD36xx (high-throughput dicing machines), or LASER (Stealth Dicing).

Grinding: DFG85xx series, suitable for power devices / sensors and other applications.

Polishing: DAP / DFP series, ideal for high-precision polishing of 8" wafers.

For 12-inch (300 mm) wafers:

Suitable for advanced CMOS / memory / 3D packaging and other high-end applications.

Dicing: DAD36xx series in large-size configuration, or Laser Stealth Dicing (low-stress, high-precision cutting).

Grinding: DFG87xx / 89xx grinding machines, often equipped with automatic loading/unloading systems.

Polishing: DFP series (300mm precision polishing), or DBG (Dicing Before Grinding) integrated solution.

Advanced laser technologies such as Stealth Dicing (SDA) may be used for large-scale dicing of 12" wafers.

Compared with competitors,

DISCO's main rivals in the fields of dicing, grinding, and polishing include Accretech (Tokyo Seimitsu), ADT (Advanced Dicing Tech), Kulicke & Soffa, among others.

Conclusion: How to choose the right DISCO equipment?

For mature processes (6" / 8"), the DAD / DFG series can be selected to meet most dicing / grinding needs.

For 300mm advanced processes (CMOS / DRAM / NAND), the DAD36xx / DFG87xx / DBG solutions are recommended.

For compound semiconductors (GaAs / GaN / SiC), Stealth Dicing (Laser) + dedicated grinding equipment are recommended.

DISCO holds a dominant market position in the fields of dicing, grinding, and polishing, and continuously introduces new laser/grinding technologies to meet emerging demands such as 3D packaging, compound semiconductors, and advanced packaging. Additionally, DISCO persists in developing advanced laser cutting technologies like Stealth Dicing to satisfy the ultra-thin cutting requirements of compound semiconductors and silicon wafers. Amid the rapidly increasing demand for advanced packaging, 3D packaging, and compound semiconductors (such as SiC, GaN), DISCO boasts significant technological advantages with its innovative laser cutting and DBG solutions.

Source: WeChat public account "Xiaobao's Semiconductor World"